Vacuum is not a subject offered in school, and when someone is trying to wrap their head around what a vacuum pump is and how it works for the first time, we sometimes hear the comment, “Oh, it’s a compressor that turns backwards.”

This is close. The vacuum pump is another type of air and gas compressor, but it turns in the same direction and works in the same general way: work is done on the gas.

If it’s a rough vacuum blower, a high vacuum booster, a gas booster, or an air compressor, they all provide work on the gas. Let’s try to prove it and clarify what we mean by “work on the gas”.

Before we get there, let’s discuss the term “Throughput”. In the high- and ultra-high-vacuum world, this is also known as the mass flow rate.

Q = P * S

Q= Throughput

P = Pressure

S = Volumetric Flow Rate

Technically, throughput is not a mass flow rate; it is normally expressed as the true weighted gas flow (e.g., 10#/h air). In vacuum technology, throughput (Q) is fundamentally a measure of the molar flow rate (particle flow rate), but it is frequently treated as a “mass flow” equivalent because it represents a conserved quantity of matter moving through the system.

Using the ideal gas law (PV = nRT), we can express throughput in terms of the number of moles (n).

Ideal gas law PV = nRT

P = Pressure

V = Volume

n = moles

R = Universal gas constant

T = Temperature

Q =PV/t = nRT/t

t = time

If the temperature (T) is constant, (Q) is directly proportional to n/t, which is the molar flow rate lb-moles/hr

Molar flow rate = lb-moles/hr = molecular count rate

We’ve set the table for a better understanding of what “work the gas” means.

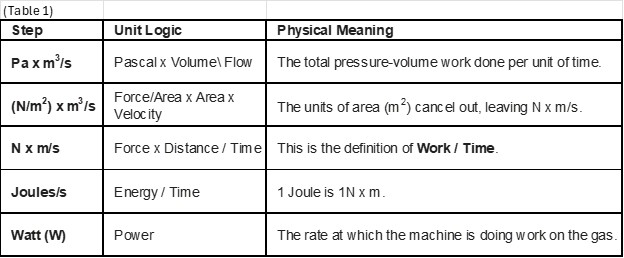

From Table 1, we can see that the first step shows the throughput (Pa * m3/s) and describes the work done on the gas per unit time.

Step by step, we are proving that Joules per second are the units of energy/time, and finally that Watts is the rate at which the machine is doing work on the gas.

And what do we mean by work done on the gas? Every compression machine starts with a lower inlet pressure and compresses it to a higher discharge pressure, so it is technically compression work.

Any compression-type machine = vacuum pump (effectively acting as a sub-atmospheric compressor), air compressor, vacuum booster, rough vacuum blower, booster compressor, gas compressor, etc.

To learn more and review your application, contact us.