Let Vooner share our Know-How and Partner with you to maximize reliability, sustainability, and energy conservation for the heart of your paper-making process = Your press section

Sustainability

- Identify all Input materials, resources and operating expenses to make product.

- Account for Inputs that are a part of Finished product

- Inputs lost and not in Finished product is Loss of Sustainability

- Full Sustainability is all inputs are in finished products.

Energy Conservation

- Measure Power Input and Cost

- Calculate working power by subtracting drive slippage, leaks friction losses, and heat losses and the Financial Cost.

- Calculate remaining and available Power Consumed

- Energy Conservation rating is Power Consumed / Power Input

Return on Equipment Investment

- Initial investment of equipment and installation as Investment

- Add to investment cost, if removal of former existing equipment

- Measure for normal operating time all Expenses of power, water, operating labor, maintenance labor and depreciation.

- Plan operating time before major maintenance or replacement

- Operating cost for depreciation time (7 years) and long term (20 -30 years) including all major maintenance or replacements.

- ROEI for a time is initial Investment / total operating plus maintenance Costs plus major maintenance or replacement investments

Sustainability and Energy changes in Paper Mill vacuum systems are surprising and rewarding

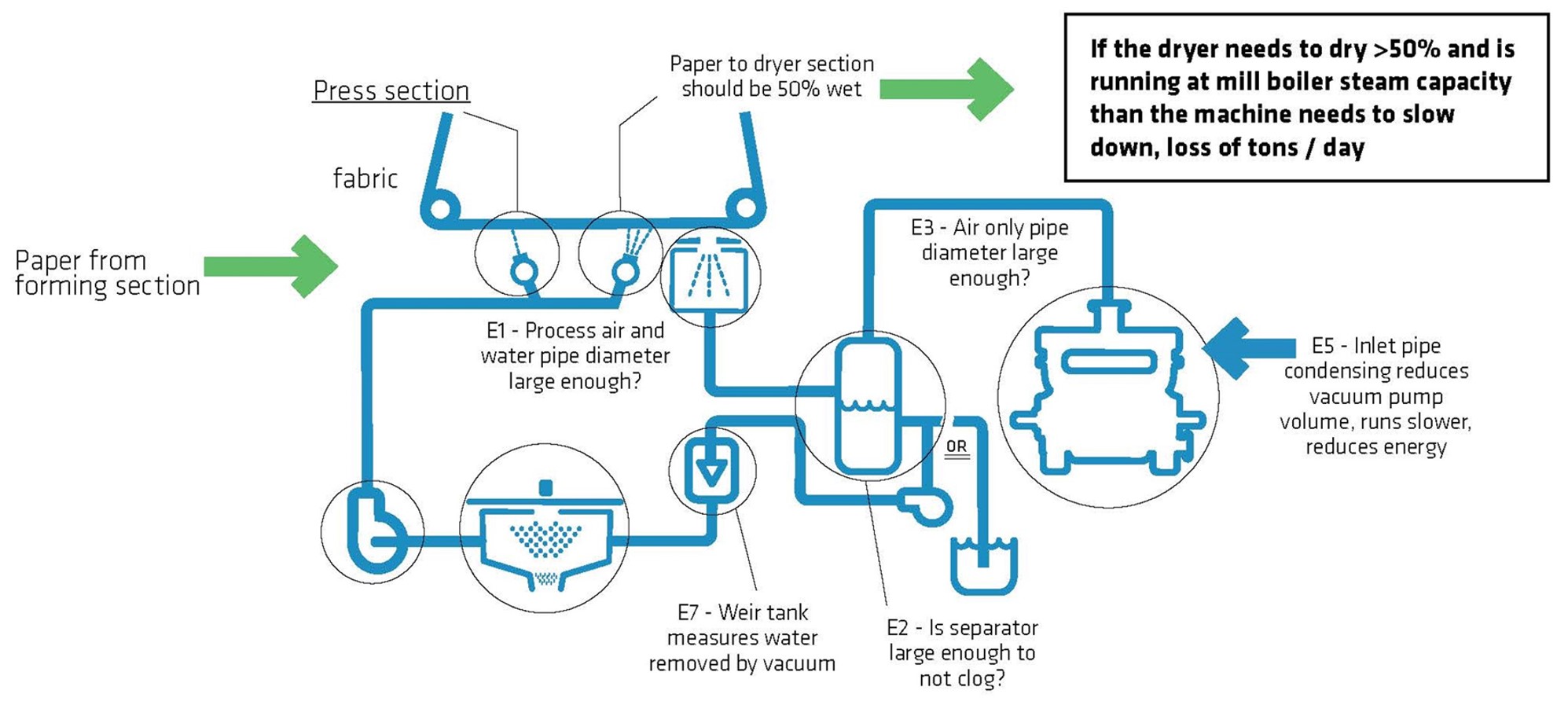

- Energy balance by maximizing mechanical removal of water and minimizing thermal evaporation of water

- Cool and condense vacuum process vapor into water to reduce vacuum volume

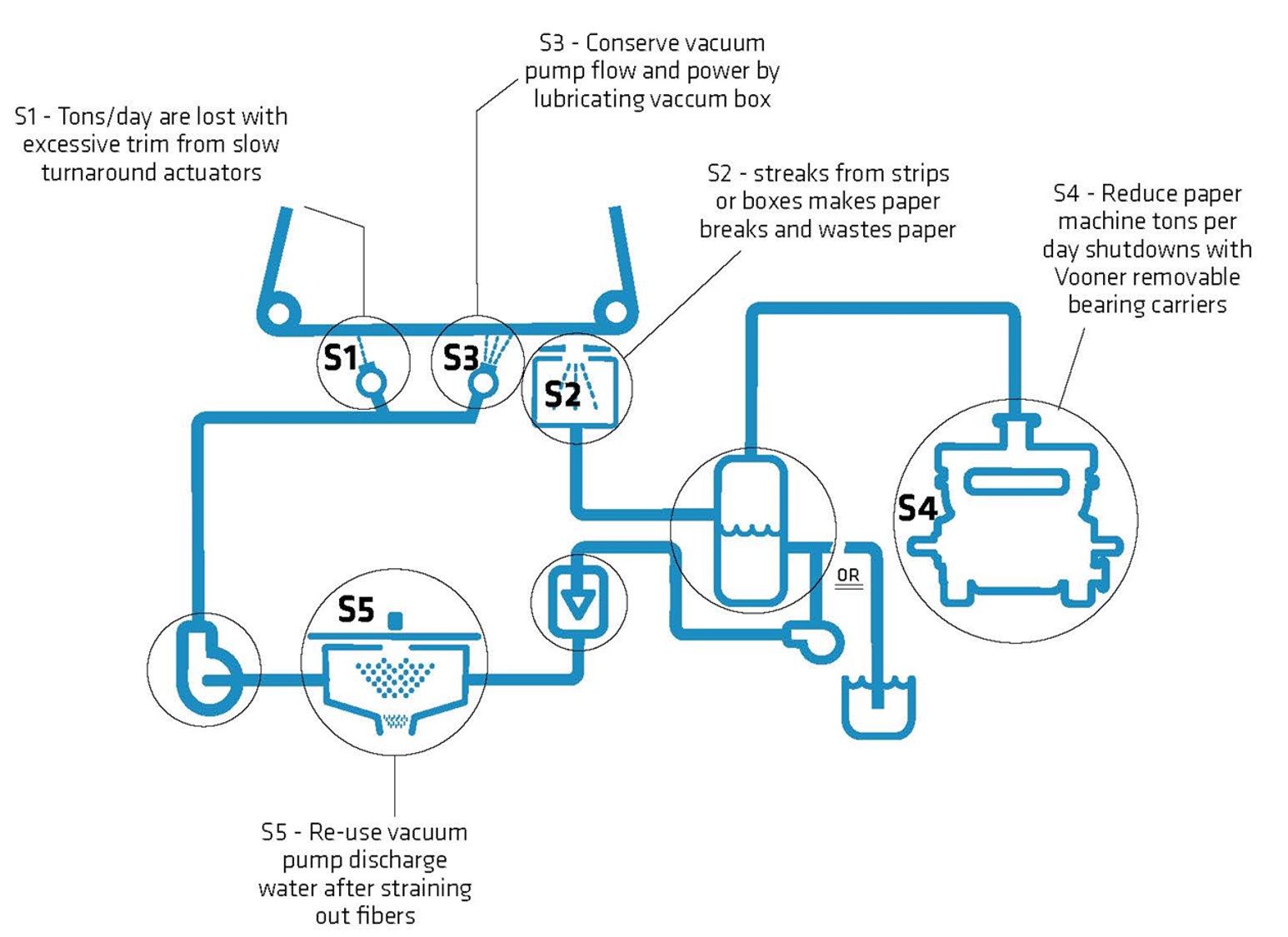

- Fine tune adjustments at dewatering contact point to improve dewatering

- Reduce trim of product at edges of process by using fast reverse actuator

- Recirculate vacuum pump seal water, clean with gravity strainer removal of suspended solids, for warmer process water

- Collect and heat exchange vacuum pump discharge water to recover heat

Improve SUSTAINABILITY of raw materials or finished materials

Waste of input materials and reducing end Product

Conserve system ENERGY on paper machine

Removing water mechanically by vacuum consumes 1/4 the energy needed to thermally evaporating the same amount of water in the dryer.

Vacuum Rotary Drum Filter

Changes in vacuum systems are Surprising and Rewarding

- Rotary drum filters separate slurry solids from liquids

- Valuable solid cakes removed are corn starch, minerals, coal, gypsum

- Valuable liquids removed are phosphoric acid, clear water from aerobic wastewater treatment plant

Condenser Exhauster Vacuum of Non-Condensable gases

Changes in vacuum systems are Surprising and Rewarding

- For steam turbine power plants

- Vacuum removal on NCG from the condenser improves the performance of the steam turbine

- Performance of vacuum to 1” mercury is the optimal performance.

- For every vacuum level higher than 1” Hg vacuum is significantly costly for the power company.