Liquid ring refers to a type of vacuum pump that uses a rotating ring of liquid to make pistons compress the gas captured. Liquid ring pumps are used in industrial applications, including vacuums for liquid-solid separation in filters, pneumatic conveying, distillation, and vaporized drying.

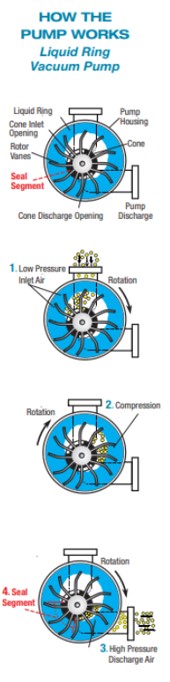

The pump consists of an impeller or rotor with vanes that rotate within a casing or housing partially filled with liquid, typically water. The liquid is supplied to the pump and then is thrown outwards by centrifugal force, forming a series of liquid pistons working off the inside wall of the casing.

Gas enters the inlet of the pump by high-velocity kinetic energy. As the impeller rotates, the water pistons compress the captured inlet gas. The gas or air is continually compressed in the spaces between the liquid and the impeller blades, pushed around the casing at a pressure greater than the external pressure, and discharged at the outlet of the pump.

One advantage of liquid ring pumps is that they can handle vapors containing solids or non-condensable gases. Liquid ring pumps also operate at a noise level equivalent to the pump motor and require little maintenance. Liquid ring vacuum pumps are commonly used in paper mills for various applications, such as forming and dewatering press section fabrics.